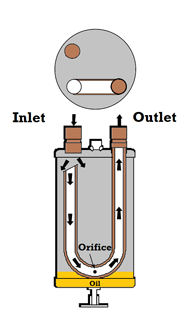

The specific type of accumulator is shown by the additional symbols within the oval, as shown in figures 2, 3, and 4. The symbol for a fluid energy storage or absorption device is the extended oval shown in figure 1. The three types of preloading are weights, springs, and gas. This must also be relieved or isolated.Īccumulators are preloaded so that there will be a minimum pressure for any available fluid. When hydraulic pressure is relieved, there is still stored energy in the gas. The energy must be released or isolated before any work is done on an accumulator or on components that may be connected to an accumulator.

There is the potential for the sudden, uncontrolled release of energy whenever working with or around hydraulic accumulators. They also absorb and dissipate energy when used to dampen pressure pulses, reducing noise and vibration. Accumulators can be used to absorb the expanding fluid and/or supply the contracting fluid. If a volume of fluid is confined and unable to expand or contract due to temperature changes, there could be very high pressure that could damage equipment or low pressure that could cause air bubbles in the hydraulic fluid. Hydraulic fluid has a relatively high rate of thermal expansion. A low-pressure accumulator can receive a portion of the flow and then discharge it at an appropriate rate for the plumbing. The returning flow from a large-bore cylinder may be greater than should be conducted by the plumbing. There are several ways in which accumulators are used to absorb energy. It could be used to hold pressure in a system when pump flow has stopped by providing fluid to compensate for leakage.

This could be for emergency power when pump flow is not available. Other times the stored energy is kept in reserve until it is needed and may be independent of pump flow. Sometimes accumulator flow is added to pump flow to speed up a process. When storing energy, they receive pressurized hydraulic fluid for later use.

They are used to store or absorb hydraulic energy. Posted on by Fluid Power Journal in Test Your Skills 1 CommentĪccumulators come in a variety of forms and have important functions in many hydraulic circuits. Also, check out our video on the Total Superheat Method.

#Accumulator on a splitt system full#

Check out our full article on the Total Superheat Charging Method. If the system has no superheat, the refrigerant will be saturated (Saturated means that both liquid and vapor refrigerant exist in the same location) so the vapor compressor will get damaged by the saturated refrigerant entering it. Remember that if a system has superheat, the refrigerant entering the compressor will be in vapor form. Liquid refrigerant entering a vapor compressor will damage it. In that scenario, you must set a fixed orifice system at an inefficiently high superheat just in order to keep the compressor safe from having liquid refrigerant enter the vapor compressor. If you were to take an indoor WB and outdoor DB measurement in a dry climate, and line them up on a target superheat chart, you will likely see that the target superheat is not on the chart, meaning that the target superheat number for the system is too low to print (such as 5☏ or lower). The target superheat is a moving number so it will depend on the Indoor Wet Bulb Temp and the Outdoor Dry Bulb Temp. When charging a system with a fixed orifice, the target superheat needs to be determined.

0 kommentar(er)

0 kommentar(er)